مدونة الموقع

اتصل بنا

- إذا كانت لديك أسئلة، يرجى الاتصال بنا، وسيتم الرد على جميع الأسئلة

- البريد الإلكتروني : David@tmaxcn.com

- البريد الإلكتروني : Davidtmaxcn@gmail.com

- إضافة : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

المنتجات الساخنة

Lithium batteries have become an essential part of our lives, powering everything from our smartphones to electric vehicles. As the demand for lithium batteries continues to rise, there is a need for efficient and reliable lithium battery manufacturing machines. In this article, we will discuss the technology behind lithium battery manufacturing machines and their various components.

Lithium Battery Manufacturing Machine Technology

The lithium battery manufacturing line is an automated system designed to manufacture lithium batteries efficiently. The machine is composed of several components that work together to produce high-quality lithium batteries.

The electrode coating machine is responsible for coating the electrode with a thin layer of active material. The machine applies the active material to the electrode using a roller or doctor blade. The active material is a critical component of the battery and is responsible for storing and releasing the energy. The electrode coating machine must ensure an even and consistent coating of the active material on the electrode.

The electrode slitting machine is responsible for cutting the coated electrode into the desired width. The machine uses a high-speed rotary blade to ensure accurate and precise cutting of the electrode. The electrode slitting machine must ensure the electrodes are cut to the required size and shape.

The electrode stacking machine is responsible for assembling the electrodes into a stack. The machine places the electrodes in the desired order and orientation to ensure the battery's optimum performance. The electrode stacking machine must ensure the electrodes are precisely aligned and stacked in the correct order.

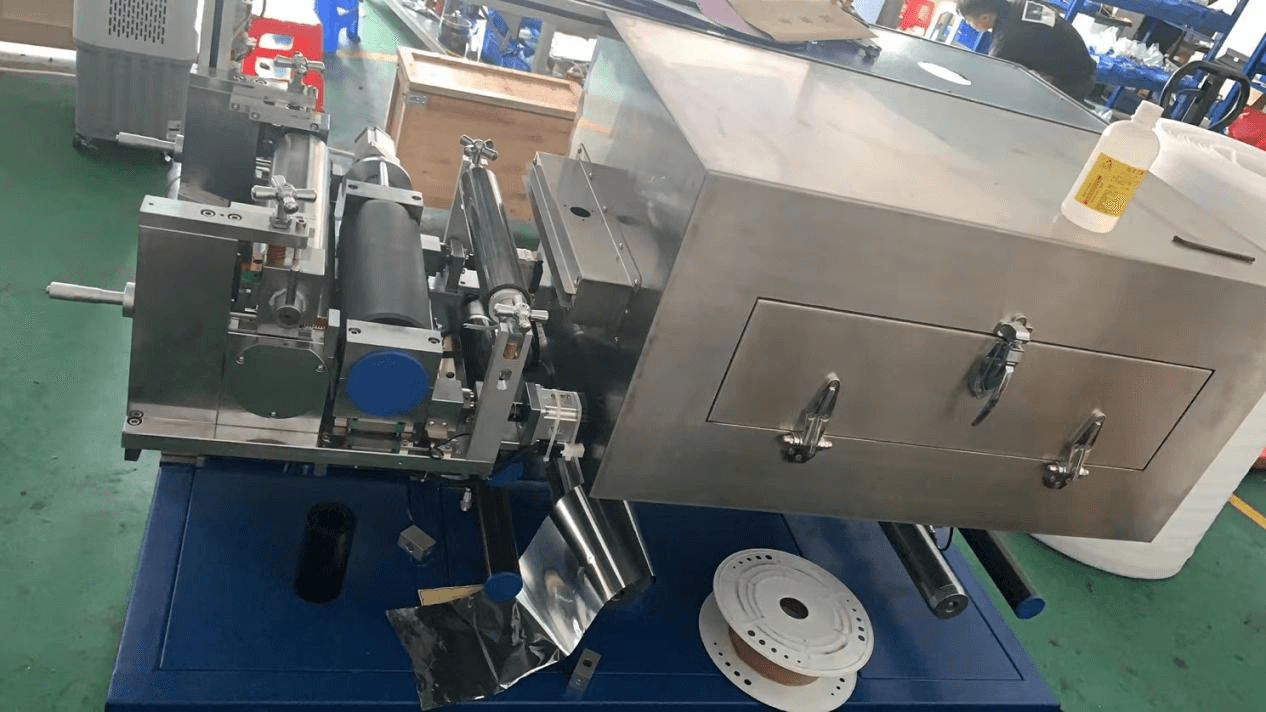

Battery Cell Winding Machine

The battery cell winding machine is responsible for winding the stacked electrodes into a cylindrical or prismatic shape. The machine applies tension to the electrode stack while winding it onto a core or mandrel. The battery cell winding machine must ensure the electrode stack is wound tightly and consistently.

Battery Cell Tab Welding Machine

The battery cell tab welding machine is responsible for welding the tabs of the electrode stack to the current collectors. The machine uses a combination of heat and pressure to ensure a reliable and consistent weld. The battery cell tab welding machine must ensure the tabs are welded securely and without damaging the electrode.

Battery Cell Formation Machine

The battery cell formation machine is responsible for charging and discharging the battery cells. The machine applies a precise charge and discharge cycle to the cells to ensure they are fully functional and meet the required specifications. The battery cell formation machine must ensure the cells are charged and discharged to the correct levels to maximize performance and lifespan.

The battery pack assembly machine is responsible for assembling the battery cells into a complete battery pack. The machine connects the cells in the required series and parallel configurations and adds the necessary protection circuitry. The battery pack assembly machine must ensure the battery pack is assembled safely and efficiently.

Battery Pack Testing Machine

The battery pack testing machine is responsible for testing the completed battery pack. The machine applies a series of tests to the battery pack to ensure it meets the required specifications. The battery pack testing machine must ensure the battery pack is safe and reliable.

Lithium battery manufacturing line are critical components in the production of high-quality lithium batteries. These machines must be efficient, reliable, and precise to ensure the batteries meet the required specifications. The components of the lithium battery manufacturing machine work together to ensure the battery cells and packs are assembled accurately and safely. As the demand for lithium batteries continues to rise, the development of new and improved lithium battery manufacturing machines will play an essential role in meeting that demand.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com